——Welcome visit our factory

After the product is assembled, it is tested by automatic test equipment.

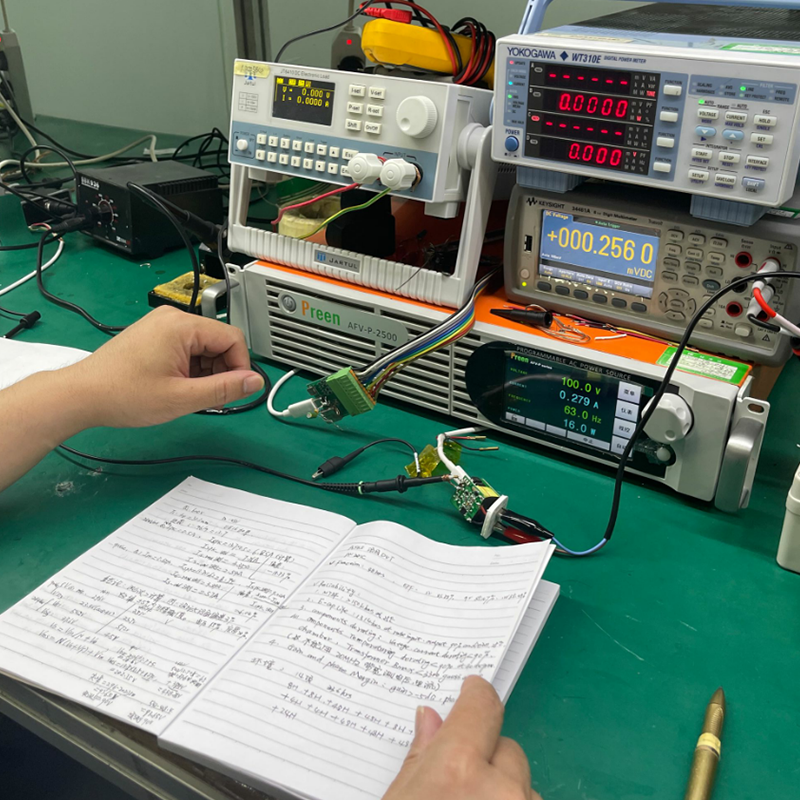

R & D Center

After the plug-in is completed,the PCBA enters the wave soldering equipment through the automatic conveyor belt for automatic soldering

The Plug-in production line,each operator wears an anti-static wristband, and each position has a corresponding operating SOP..

We have a strong R&D team that can provide customized services for customers. Customized service can be an adapter or PCB BOARD.

Trim excess

Laser printing

After the product is assembled, it is tested by automatic test equipment.

Check the appearance of the ac dc power adapter

Output Testing

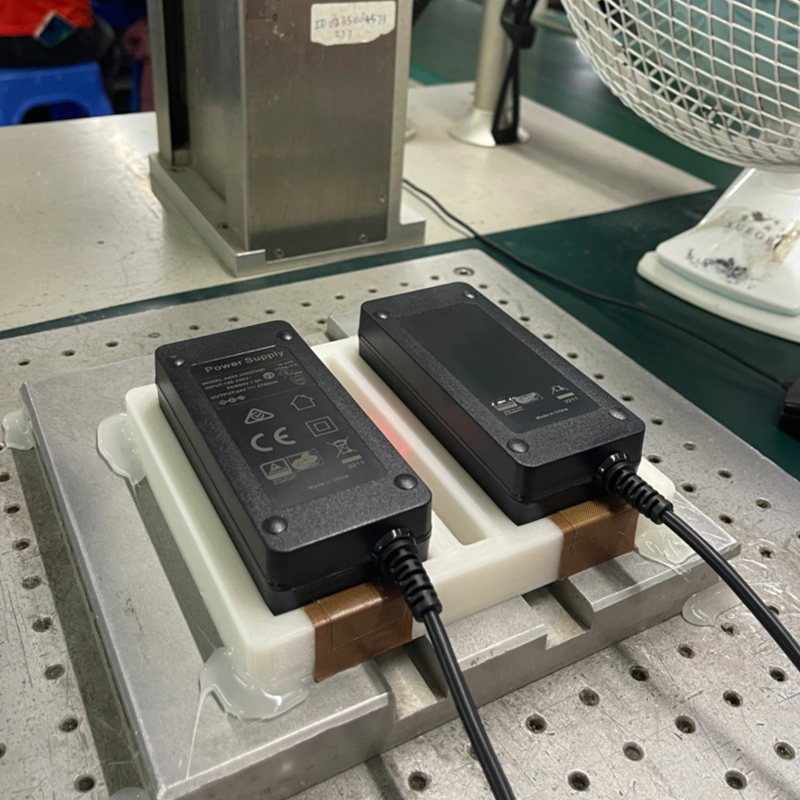

Aging workshop with constant

temperature of 40 degrees

100% of the power adapters after assembly production move to the aging workshop and age in the constant temperature 40C workshop for 2 hours.

Through automatic testing system of the computer sets the high-bottom pressure impact test. After the power adapter passing the automatic testing system, proceed to the packaging production line to complete the subsequent production.

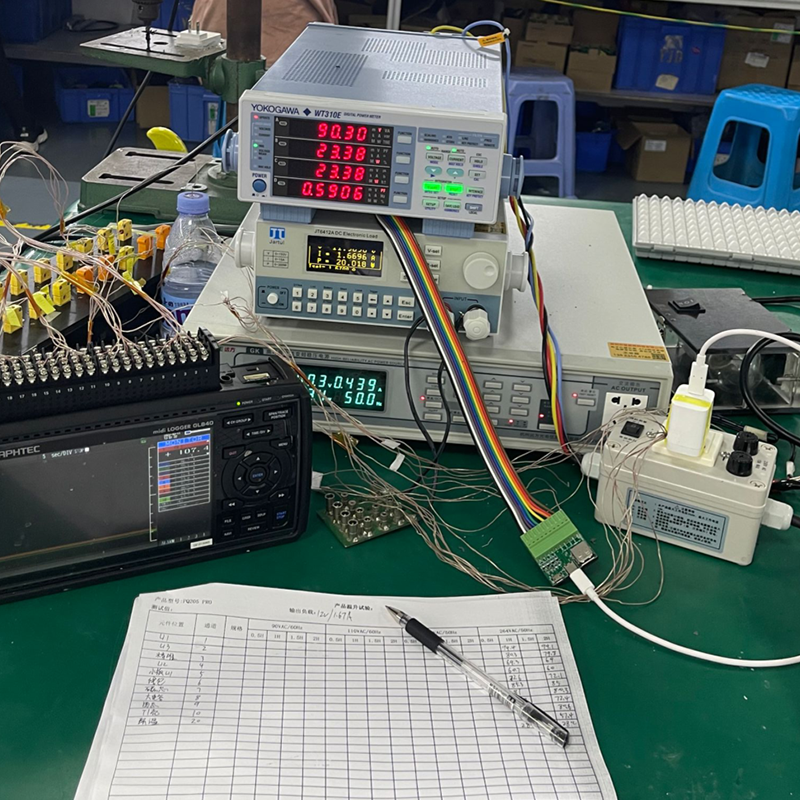

250W desktop power supply is debugging

GaN charger temperature rise is testing

30W GaN charger is debugging

Laboratory

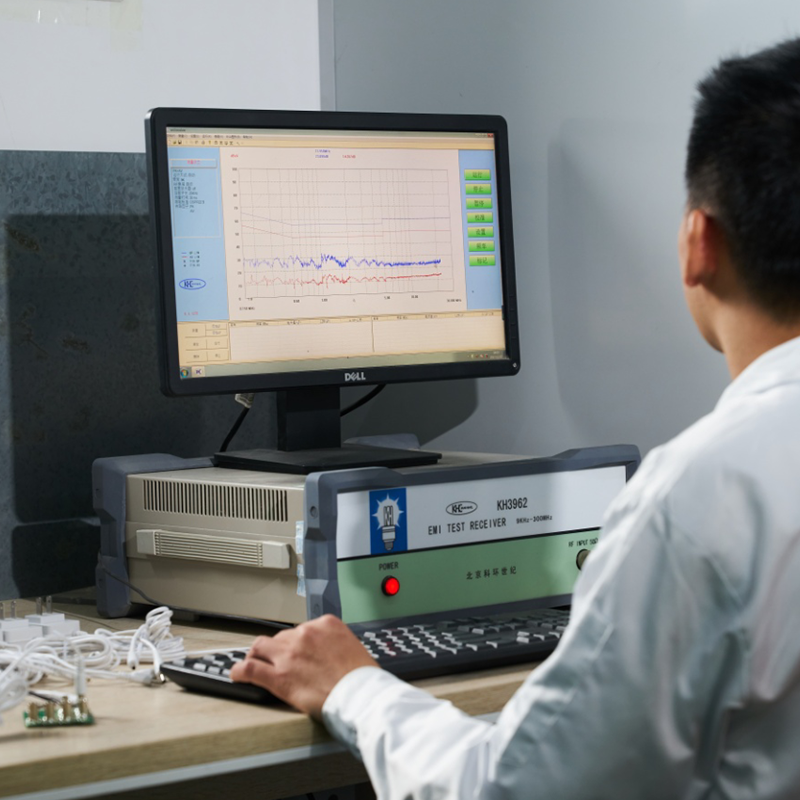

EMC Testing

Conducted Radiation

High temperature and low temperature testing

ESD test (Electrostatic test)

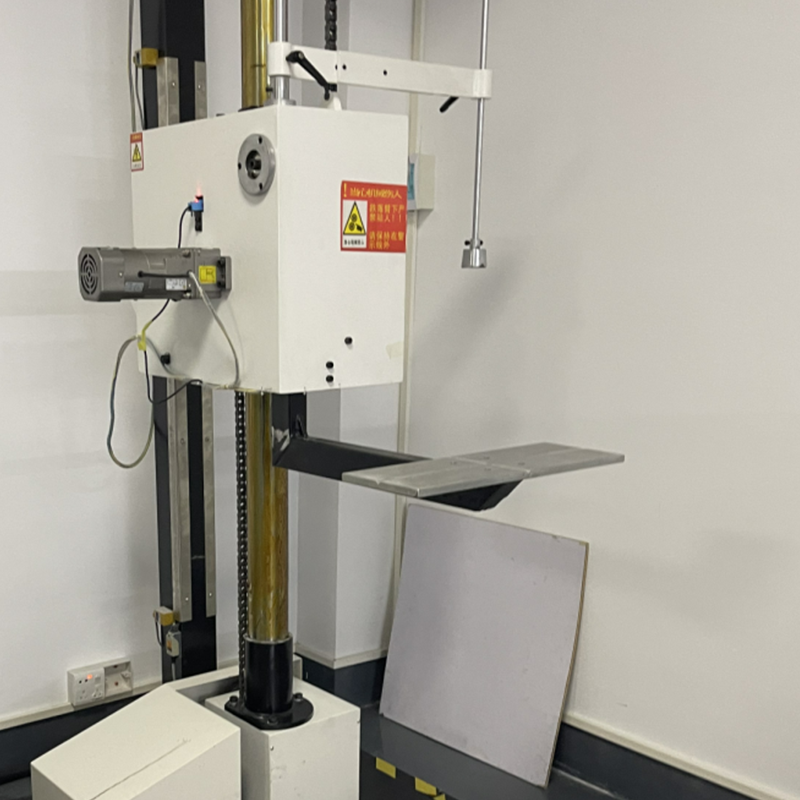

Drop Test